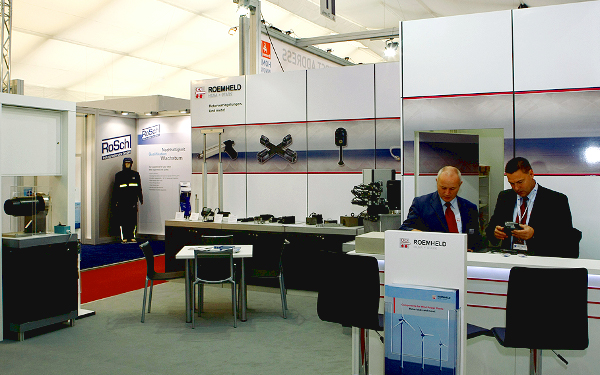

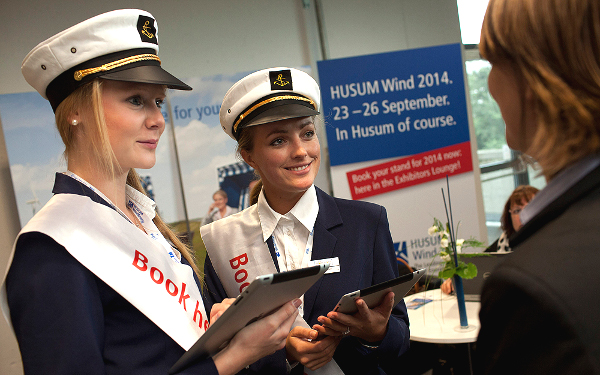

Clamping technology experts ROEMHELD are delighted with the turn-out at the Husum WindEnergy trade show. ROEMHELD presented their new products for the testing and maintenance of large wind turbine components at the show, including "Rotorlocks" and linear actors for flap and azimuth adjustment. The company has received a large number of enquiries and is involved in in-depth discussions with both German and international companies which have expressed a keen interest in these solutions. ROEMHELD is one of the world's largest providers of solutions for production, assembly, clamping and drive technologies.

Broad applications for "Rotorlock"

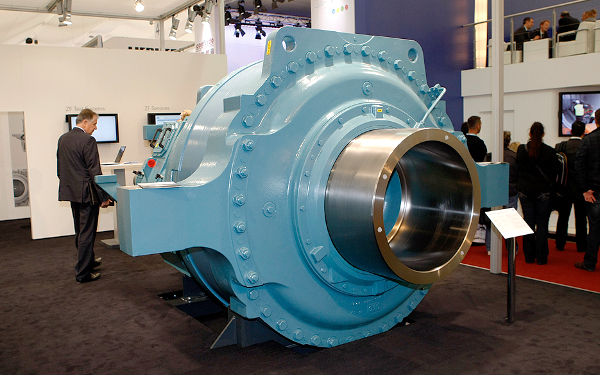

The compact hydraulic "Rotorlock" systems are based on standard components made by ROEMHELD. With just minor modifications, they are suitable for a number of commercial wind turbines, which makes these systems excellent value for money.

Features include easy handling, load-bearing capacity for transverse forces up to 5,500 kN and safe locking of rotors for wind turbines of 6 MW and more. In addition to the "Rotorlock" design which was exhibited at the show, ROEHMELD also offers an electromagnetic version. Many customers are already using ROEMHELD's locking elements to clamp large components during production.

Linear drives for a full range of applications

Linear actors were met with great interest as well. Uses include moving maintenance openings and azimuth adjustment. ROEMHELD offers an ample portfolio of standard designs with either hydraulic or electro-mechanical drives.

For safe maintenance and locking of wind power plants, on-shore as well as off-shore, the ROEMHELD Group develops and manufactures at the site Hilchenbach, beside customer-specific solutions for rotor locking also clamping elements for the rotor blade production - of course all completely "made in Germany".

Suitable for wind power plants with six megawatts of power and more

The rotor lockings for inspection and maintenance tasks consist of standard modules, which are configured according to an integrated concept. Thus, even complex special designs are available within a short time and at a reasonable price. The elements are based on a hydraulic or electro-mechanical design, double-acting bolt with position monitoring, that reliably locks the rotor with forces of up to 4,900 kN. Options for adjustable position monitoring or additional mechanical locking are available.

The lockings are designed for the use at temperatures between -30° C and + 70° C and maintenance free. Adapted to the limited space in the nacelle, their design is extremely compact. The ROEMHELD Group manufactures all rotor lockings as per customer's specification in Germany and delivers them to consumers all over the world.

The locking systems are available as on-shore or off-shore version, both with a special surface coating as per the requirements of DIN EN ISO 12944. By means of a special corrosion-resistant coating, safety and reliability can be guaranteed for long periods of time. Hilma follows the average operating time of off-shore plants of approx twenty years or the specific customer requirements.

ROEMHELD being worldwide the largest supplier of products for production, assembly, clamping and drive technology will present for the first time at this years‘ Husum WindEnergy fair an extended range of elements for testing and maintaining large-scale components for wind turbines. The hydraulically or electromechanically driven rotor lock made by ROEMHELD has already been launched with great success. Designed to withstand lateral forces of up to 5,500 kN, the rotors of onshore and offshore turbines with a capacity of six megawatt or more are reliably and safe locks. Furthermore, thanks to its compact design it is perfectly adapted to the limited space in the nacelle.

Germany-based firm ROEMHELD manufactures all products to meet customers‘ specific requirements and supplying them to purchasers right around the world. In view of the fact that standard components are used, even special designs can be quickly and cost-efficiently produced.

Among the potential fields of application are clamping elements for dies and workpieces used for the production of large-scale components, hydraulic test stands for rotor brakes, rotor locks for onshore and offshore turbines and linear actuators for moving maintenance flaps. All these items will be on display at stand 1C09 in hall 1.

About ROEMHELD

The product portfolio of ROEMHELD, the world’s leading experts in the field of clamping technology, comprises production, assembly, clamping and drive technology for the production industries. At their sites in Laubach, Hilchenbach and Götzis (Austria) the ROEMHELD Group develops and manufactures customized solutions for production automation. The market leader is represented in more than 50 countries on all continents by sales and service companies. In 2011 total sales of some 86 million Euros were achieved by 450 members of staff.